- 360° Rotatable

SANPAR has the expertise and proven track record to design and manufacture dryers to supply clean dry air using the techniques of Adsorption process. Adsorption Drying is a process which is very popular and tested from immemorial. It is a reversible process. Moisture is adsorbed during the drying cycle and desorbed during the regeneration cycle.

Hence there are two towers: while one in the process of drying, the other is on the regeneration mode.

Fill the form to download brochure

SANPAR design team put in their experience to design to deliver suit- the individual- application dryers.

Low pressure drop and low purge loss Along with least power consumption is the hallmark of SANPAR Dryers.

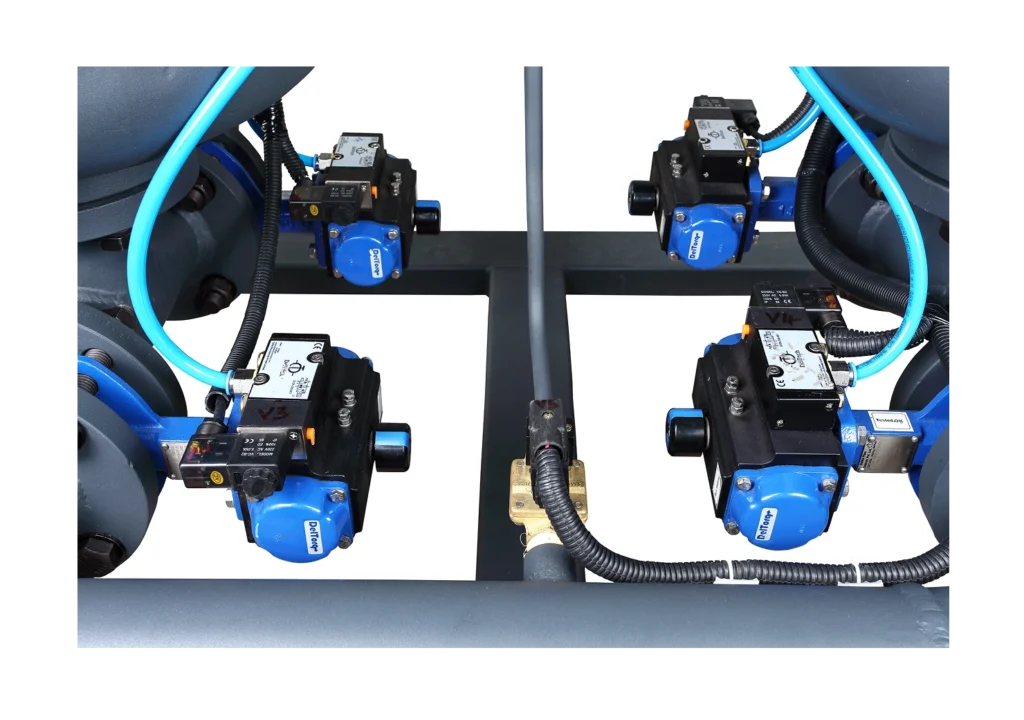

The heart of the Adsorption dryers consists of Desiccants, Pressure vessels, Directional Valves and the control logic.

The desiccants deployed are Molecular sieves, Activated Alumina or Silica gel.

The dryers can be designed to deliver bone dry air up to the dryness of (-) 70 deg C

Adsorption dryers could be categorized in to additional categories:

- Pressure Swing Adsorption / Heatless Dryers

- Heat of Compression Dryers

- Blower reactivated Air Dryers

- No- purge- loss Adsorption Dryers

Adsorption dryers are tailor designed to meet the individual requirements:

- The quality of dryness required for a particular application

- The type of Air Compressors used – Lubricated or Non lubricated

- The operating pressures

- Operating temperatures

Technical Specification are for the following standard conditions

- Operating Pressure > 7 Bar g

- Pressure Dew Point : -60°C

- Air Inlet Temperature: 45°C

- Condenser Cooling Air Temperature : 40°C