- 360° Rotatable

The compressed air discharged from an air compressor is hot. Compressed air at these temperatures contains large quantities of water in vapour form. If this is not removed, much of it will condense in the distribution system and cause expensive damage to all the equipment and processes, which use the air.

Fill the form to download brochure

As the compressed air gets cooled in the after- cooler, where the cooling media is the ambient air or water from a cooling tower, the water vapour condenses into a liquid form. As an example if an after cooler is not used, a 200 SCFM compressor operating at 7bar (g) introduces 170 – 240 liters of water into the compressed air system each day. Atmospheric air is used to cool the compressed air in an Air Cooled After Cooler.

Salient features of SANPAR After Cooler (Air Cooled)

- Highest quality copper tubes are used for effective heat transfer and durability

- Removable tube bundle

- Revolutionary tube inserts in each cu tube for enhanced heat transfer

- Liberally positioned ss 316 baffle plates for effective heat transfer

- Highly reliable fan assembly with protective guard

- More than 10 standard models to choose from to meet individual requirement

- Compact models: occupies less floor space

- Higher models on request

Technical Specification are for the following standard conditions

- Operating Pressure > 7 Bar g

- Outlet air temperature : 10° above ambient

- Air Inlet Temperature: 120°C

- Water Cooling : 85° c

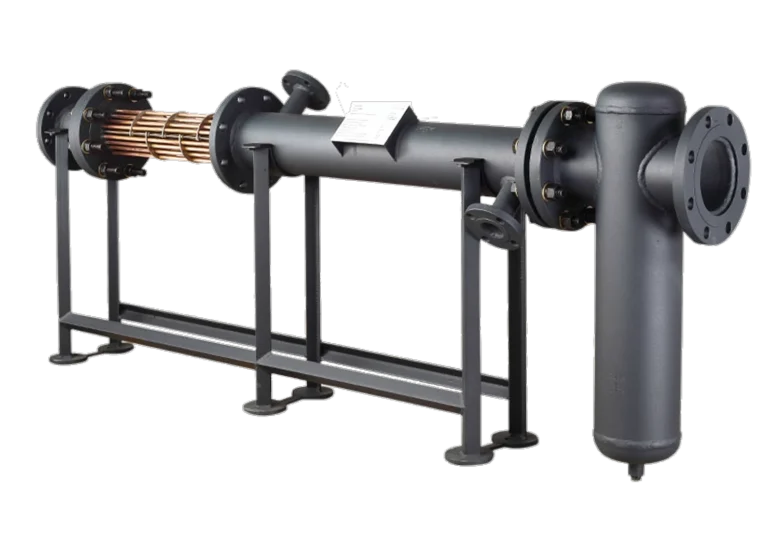

Aftercooler Watercooled

Water from a cooling tower is used to cool the compressed air in a Water Cooled After Cooler. SANPAR make Water Cooled After Coolers are all custom made, hence complete flexibility in design considerations to suit the customer’s requirements.

Salient features of SANPAR After Cooler (Water Cooled)

- Highest quality copper tubes are used for effective heat transfer and durability

- Removable tube bundle

- Revolutionary tube inserts in each cu tube for enhanced heat transfer

- Liberally positioned ss 316 baffle plates for effective heat transfer

- Silver brazing rods used for efficient thermal conductivity

- Low pressure drop (less than 0.1 bar)

- Low maintenance

- Highly compact and efficient design

- Design compliance to same section viii - div 1

Technical Specification are for the following standard conditions

- Operating Pressure > 7 Bar g

- Outlet air temperature : 10° above ambient

- Air Inlet Temperature: 120°C

- Water Cooling : 85° c